Allroad Motorcycle TYRES

Allroad motorcycle tyres play a clear role in riding. The tyres almost dictate what kind of surfaces generally could be ridden with confidence. There are a lot different kind of tyres that provide a different kind of combination of tyre features such as contact surface patterns (tread), grip on wet or dry, operating temperature, side wall support and durability etc. Everything in tyres points to 3 factors called traction, comfort and durability. Generally touring tyres offer more grip at lower temperatures and are made of harder rubber compounds which provide longer durability, but also slightly less traction compared to softer tyre compounds.

Allroad Motorcycle TYRES Tubeless

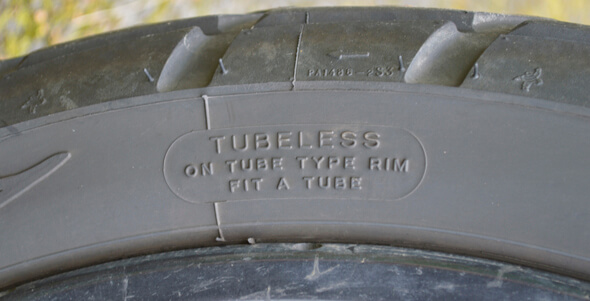

There are 3 kind of tyres that require different kind of attention and may even limit options along the road. Today the most common tyre type is the tubeless tyre which has no additional inner tube inside the tyre. The wheel itself must be air tight and the valve is sealed together with the wheel. The tubeless tyre bead is sealed against the wheel using special ribs that are forced with the air pressure against the flanges of the rim. When using tubes with a tubeless tyre that does not permit it, there is a high risk of tyre deflation which can be very dangerous while riding. The inner tube will cause a lot of friction agains the inside surface, build up heat and eventually burst and deflate the tyre rapidly.

Some of the tubeless allroad motorcycle tyres can be used also with an inner tube. Such tyres are usually marked both with tubeless TL and tubular tyre TT code. This is probably because the same tyres are used with traditional spoked rims that are not air tight and aluminium wheels.

The third allroad motorcycle tyre type is the traditional tubular or tube tyres that always need a separate inner tube. Those tyres are marked with TT -code and referred as on & offroad tyres. Usually they are slightly more narrow and higher tyre profiles designed for more adventurous touring on gravel and dirt roads. In addition the top speed and load rating is slightly lower.

Allroad Motorcycle TYRE Sizing

Allroad motorcycle tyre sizing is very simple coding which explains the tyre and the wheel size in question. The tyre sizing is moulded on the side wall of the tyre. For example a front tyre with a code 110/80R19 means that the tyre width is approximately 110 mm. or 4.33in., the side wall of the tyre is 80% of the width (88 mm., 3.46in) and the tyre fits to a 17 inch wheel.

Depending on rider preferences, different tyre size alternatives can be interesting and fit better to typical routing in question. For example lower tyre profiles have stiffer side walls which makes those tyre less comfortable on rough surfaces and therefore less ideal for poorly maintained gravel & dirt roads and trails. Lower tyre profiles are better on tarmac and well maintained gravel roads. Wider tyre profiles provide higher payload support on soft surfaces and carry the weight better, but also provide less grip from the hard ground below the soft layer. Wider tyre profiles are also better on tarmac and well maintained gravel roads. Narrow tyre profiles are able to exert more pressure on a smaller contact patch and reach the hard ground providing better handling features. Therefore narrow tyre profiles are better for adventure touring with a reasonable payload.

Allroad Motorcycle TYRE Markings

Motorcycle tyre manufacturers usually provide more information about the tyre characteristics with few simple codes on the side wall of the tyre or otherwise. For example the DOT -code specifies the producing factory, the mould, the batch and the production week in question. In this case below week 23/2012. Usually tyre dealer`s stocks run fast enough, but I recommend to pay attention to the production weeks, since the rubber changes in time and the rider needs also time to use the tyres before the tyres expire. Some of the typical and common markings are as follows:

- TL = tubeless tyre

- TT = tubular tyre

- B = belted bias carcass type

- D = diagonal bias carcass type

- R = radial carvass type

Allroad Motorcycle TYRE Carcass Types

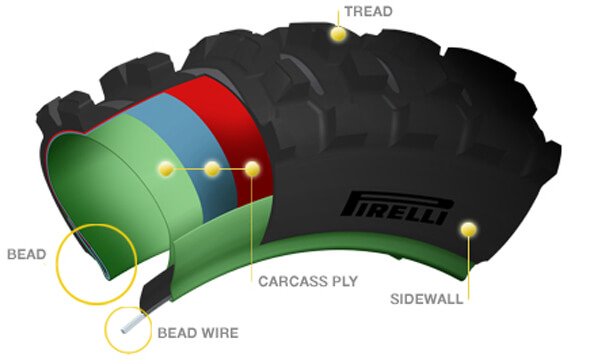

The allroad motorcycle tyre carcass carries the bike`s weight, ensures the steering stability and the riding comfort. The tyre carcass should absorb partially the hits from the ground and assist the suspension. In practice the whole suspension potential comes from the tyres, wheels and the suspension system, although the seat, foot pegs and the rider are assisting in a way too. There are 3 basic tyre carcass constructions which may be moulded on the tyre side wall. It is not a good idea to use different tyre carcass types at the same time since they have different abilities to work with the forces in question and generate steering characteristics. Some of the motorcycle frames and steering angles are even designed for radial tyres only.

Diagonal Tyre Carcass Type

The first tyre carcass type is the conventional DIAGONAL construction, also called Bias Tyre which means that the body cords extend diagonally forming a crisscross pattern from the tyre bead to bead providing smoother ride on rough surfaces which translates to slightly less control and traction at high speed. Adventure touring riders with challenging routing and demanding conditions can benefit from diagonal carcass tyres with better offroad and rough terrain features.

Bias Belt Tyre Carcass Type

The second type of tyre carcass is the BIAS Belt which is otherwise the same as the conventional Diagonal carcass, but below the tread there is a stabiliser belt providing more stiffness and control on top of a smooth ride. Allroad touring riders using the widest mix of surfaces and road conditions could benefit from the belted bias carcass tyres with advanced control and better road handling features.

Radial Tyre Carcass Type

The third tyre carcass type is the RADIAL construction which means that the reinforcing cord plies in the center of the tyre are at 90 degree angle to the direction of the travel. Below the tread there is a stabiliser belt providing better steering control. The radial cords in the side wall act like a spring giving some flexibility and riding comfort at higher speed and the side wall functions independent from the tread. At a low speed the radial tyre is slightly hard and provides less traction. The radial tyre construction is lighter and offers the best road handling features. Allroad touring riders with mostly urban routing would benefit the most of a radial carcass tyre construction.

The tyre construction determines the maximum load and the speed rating in question for a specific tyre. The maximum tyre load index is given with the first 2 digits such as 57V or 59H. The tyre load index refers to a top weight that can be used with the tyre. For example a 57 load index means a top weight of 230 kg and the 59 means 243 kg. Look at the manufacturer`s load index chart to check the tyre you have in mind. The speed rating refers to a top speed limit suitable for the tyre and for example the speed rating H means a top speed of 210 km or 130 mph classification and the V rating 240 km or 150 mph.

Allroad Motorcycle TYRE Contact Patch

The size and the shape of the tyre contact patch or the footprint (tread pattern) has a significant effect on motorcycle handling and traction properties. The biggest difference can be seen in offroad conditions when soft or rough terrain surfaces come in question. The best grip and traction on rough surfaces comes with a lower tyre pressure which allows the tyre to adopt the rough forms on the ground and build up a larger footprint to carry the weight. Lower tyre pressure provides also more comfort in riding. On tarmac surfaces the best handling and traction is established with the normal tyre pressure which is usually provided by the motorcycle and the tyre producer.

There are basically 2 things that effect on the size and shape of the tyre contact patch against the ground. The first factor is the payload. The higher the payload, the larger the contact patch. The second factor is the tyre pressure in question. The higher the tyre pressure, the smaller the tyre contact patch. The size and shape, but also the tread pattern type has enormous effect on traction. The rougher the riding surface, the more higher tread lugs and wider voids between the lugs are necessary. Larger grooves and high tread lugs provide room for sand and small stones so that the tread lugs get grip from the hard ground. Today there is a wide selection of allroad motorcycle tyres with wider tread patterns and higher tread lugs for any kind of routing scenario.

The tyre durability is often very much in rider`s focus. The tread compounds are always some kind of compromise. Harder tyre tread compounds provide better durability with slightly weaker traction characteristics. On the other hand, softer tyre tread compounds offer better traction, but also weaker wearing characteristics. Read more about tyre tread patterns here.

Allroad Motorcycle TYRE Brake In

The new set of tyres performs always different compared to the old set even, if they are the same type and size. At lest they provide better grip, but if the tyres are different carcass type and have different tread pattern, the difference is significant and the rider should learn how the new tyres behave before taking the bike to the limits. Spend at least 100 km (62 miles) riding carefully and allow the tyres to warm up fully without any full throttling, hard braking or -cornering. The tyres are at the dealer installed with vaseline or similar lube in order to bring the new tyre bead easily and tightly against the rims. This means that the tyre can also slip on the rim with full throttle or emergency braking and come out of balance. After the brake in ride, let the tyres cool off properly and check the air pressure again.